Products

Glue Seal – Ziling Packaging

Glue Seal – Ziling Packaging Detail:

Glue Seal

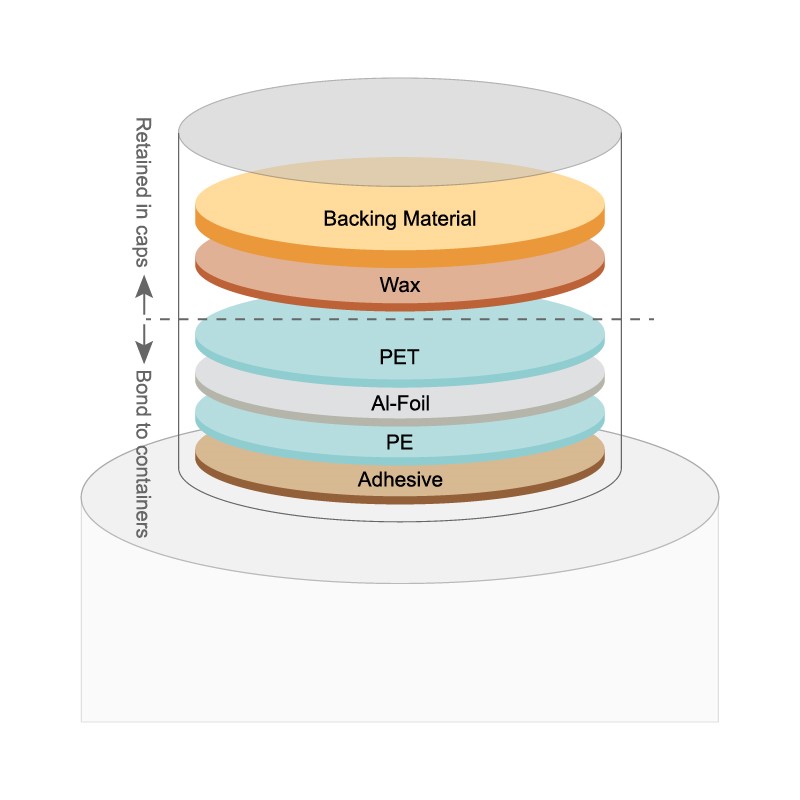

The glue seal can be made into a single piece or two pieces according to customer needs. There is a layer hot melt adhesive coated on the sealing layer of the aluminum seal liner. After heating process by the induction seal machine or electric iron, the adhesive layer will be sealed on the lip of the container. This type liner is available to all kinds of material container., especially for the glass container, but the effects is not better than the induction seal liner.

Size

Standard Thickness: 0.2mm – 1.7mm

Standard Diameter: 9mm – 182mm

Our products can be die-cut into differnt shapes and sizes upon request.

Product Parameter

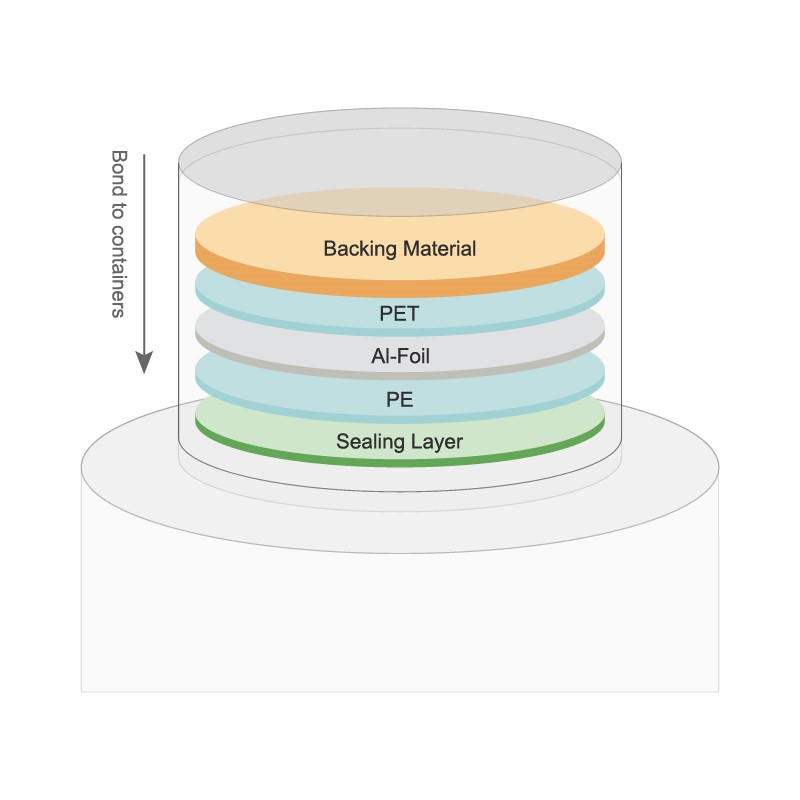

Raw material: Backing Material + Wax + Plastic Film + Aluminum Foil + Plastic Film + Sealing Film + Adhesive

Backing Material: Pulp board or Expanded Polyethylene (EPE)

Sealing Layer: PS, PP, PET, or PE

Standard Thickness: 0.2-1.7mm

Standard Diameter: 9-182mm

We accept customized logo, size, packaging and graphic.

Our products can be die-cut into different shapes and sizes upon request.

Heat sealing temperature: 180℃-250℃, depend on the material of the cup and the environment.

Package: Plastic bags – paper cartons – pallet

MOQ: 10,000.00 pieces

Delivery Time: Fast delivery, within 15-30 days which depends on the order quantity and production arrangement.

Payment: T/T Telegraphic Transfer or L/C Letter of Credit

Product Features

Good heat sealing.

A wide heat sealing temperature range.

High quality, non-leakage, anti-puncture, high clean, easy & strong sealing.

Barrier of air and moisture.

Long guarantee time.

Benefits

1. Very easy to open

2. Seals in freshness

3. Prevent costly leaks

4. Reduce the risk of tampering, pilferage, and contamination

5. Extend shelf life

6. Create hermetic seals

7. Environment friendly

Application

Packaging applications for solids, liquid, colloids, dry powders, granules, etc.

Application:

1- Food Products

2- Cosmetics

3- Glass Packaging

Recommendation:

• Nutraceutical Products

• Foods

• Cosmetics

Product detail pictures:

Related Product Guide:

Every single member from our higher effectiveness product sales staff values customers' requires and organization communication for Glue Seal – Ziling Packaging , The product will supply to all over the world, such as: Roman, Thailand, Kuwait, Make sure you genuinely feel free to send us your requirements and we are going to respond for you asap. We now have got a skilled engineering group to serve for your just about every detailed needs. Cost-free samples could be sent to suit your needs personally to understand much more information. In an effort to meet your requires, be sure to seriously feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd objects. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.