Products

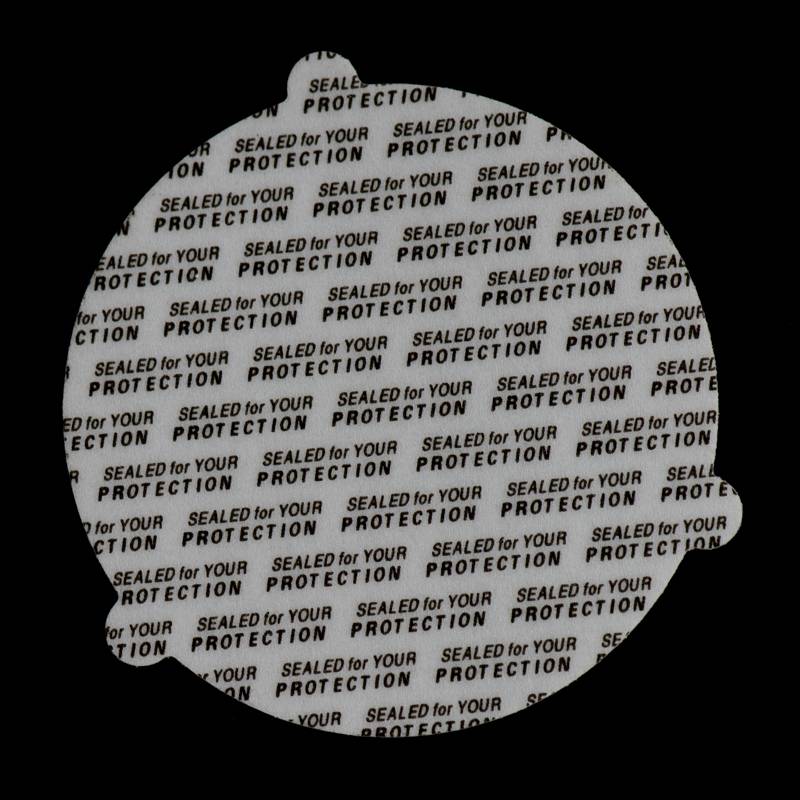

Good quality Two Piece Heat Induction Liner - One-piece Heat Induction Seal Liner with White PE Film – Ziling Packaging

Good quality Two Piece Heat Induction Liner - One-piece Heat Induction Seal Liner with White PE Film – Ziling Packaging Detail:

Function

The meaning and function of sealing lining the sealing lining, commonly known as lid lining, refers to the lid and lining material which can produce a tight sealing effect with the container. Here, containers refer to glass bottles, plastic bottles and metal cans. There are various types of covers, including screw caps, drag covers, cap caps, crimping caps, pressure caps. Lining materials refer to the materials that can close the lid and container tightly, Materials with certain requirements and specifications are absolutely free of leakage. To ensure the performance of packaged goods remains unchanged, for example, if the cover is used only and there is no lining at the bottom of the cover, the sealing effect is difficult to achieve. The function of lining is huge

Specification

Raw material: Plastic Film + PE Form + Plastic Film + Aluminum Foil + Sealing Film

Sealing Layer: PS, PP, PET, or PE

Standard Thickness: 0.24-0.48mm

Standard Diameter: 9-182mm

We accept customized logo, size, packaging and graphic.

Our products can be die-cut into different shapes and sizes upon request.

Heat sealing temperature: 180℃-250℃, depend on the material of the cup and the environment.

Package: Plastic bags – paper cartons – pallet

MOQ: 10,000.00 pieces

Delivery Time: Fast delivery, within 15-30 days which depends on the order quantity and production arrangement.

Payment: T/T Telegraphic Transfer or L/C Letter of Credit

Product Features

Good heat sealing.

A wide heat sealing temperature range.

High quality, non-leakage, anti-puncture, high clean, easy & strong sealing.

Barrier of air and moisture.

Long guarantee time.

Benefits

1. Cleaner appearance

2. Prevent liquid leakage;

3, Light weight &good sealing performance

4, Excellent chemical resistance and oil resistance

Application

Good heat sealing.

A wide heat sealing temperature range.

High quality, non-leakage, anti-puncture, high clean, easy & strong sealing.

Barrier of air and moisture.

Long guarantee time.

Recommendation

• Agrochemicals

• Pharmaceuticals

• Nutraceutical Products

• Foods & Beverages

• Lubricants

• Cosmetics, etc.

Factors Affecting Sealing

Fluid properties: the viscosity of the liquid has a great impact on the sealing performance of the packing and gasket. The fluid with high viscosity is easy to seal due to its poor fluidity. The viscosity of liquid is much higher than that of gas, so liquid is easier to seal than gas. Saturated steam is easier to seal than superheated steam because it will condense and precipitate droplets and block the leakage channel between sealing surfaces. The larger the molecular volume of the fluid, the easier it is to be blocked by the narrow sealing gap, so it is easy to seal. The wettability of the liquid on the sealing material also has some influence on the sealing. The liquid which is easy to soak is easy to leak due to the capillary action of the micro pores in the gasket and packing.

Product detail pictures:

Related Product Guide:

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for Good quality Two Piece Heat Induction Liner - One-piece Heat Induction Seal Liner with White PE Film – Ziling Packaging , The product will supply to all over the world, such as: Roman, Chicago, Algeria, Selling our products causes no risks and brings high returns to your company instead. It is our consistent pursuit to create value for clients. Our company is looking for agents sincerely. What are you waiting for? Come and join us. Now or never.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.