Products

Manufacturing Companies for Vented Seal Liners - Two-piece Heat Induction Seal Liner with Paper Layer – Ziling Packaging

Manufacturing Companies for Vented Seal Liners - Two-piece Heat Induction Seal Liner with Paper Layer – Ziling Packaging Detail:

Two-piece Heat Induction Seal Liner with Paper Layer

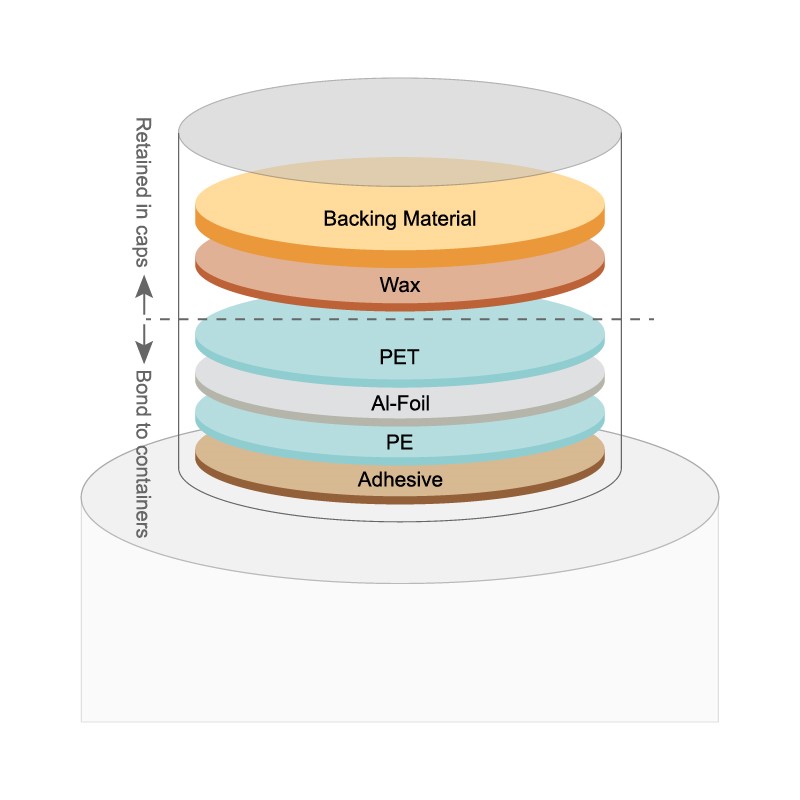

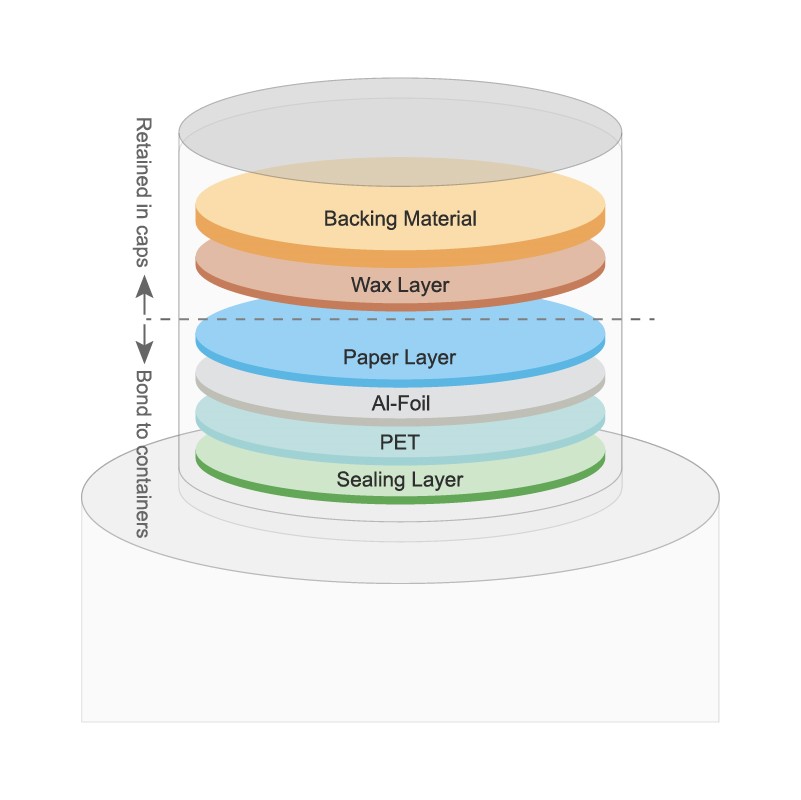

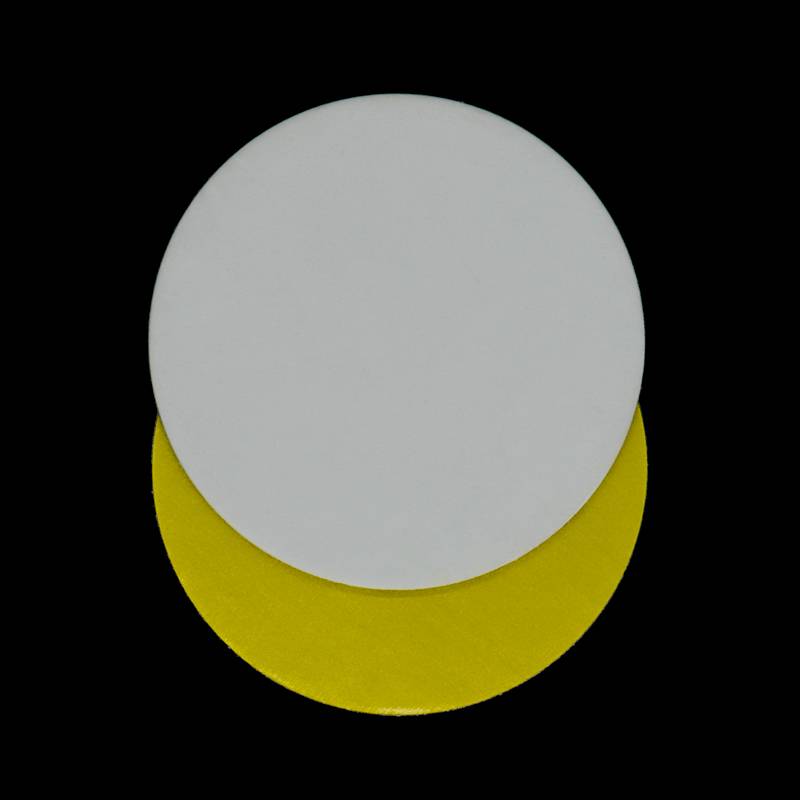

This liner is made up of aluminum foil layer and backup layer. It needs the induction seal machine. After induction machine provides a heat-seal laminate hermetically sealed to the lip of a container, the aluminum layer is sealed on the lip of the container and the secondary layer (cardboard of form) is left in the cap. The secondary liner as the reseal liner is left in the cap after heating process.

Specification

Raw material: Backing Material + Wax + Paper Layer + Aluminum Foil + Plastic Film + Sealing Film

Backing Material: Pulp board or Expanded Polyethylene (EPE)

Sealing Layer: PS, PP, PET, EVOH or PE

Standard Thickness: 0.2-1.7mm

Standard Diameter: 9-182mm

We accept customized logo, size, packaging and graphic.

Our products can be die-cut into different shapes and sizes upon request.

Heat sealing temperature: 180℃-250℃, depend on the material of the cup and the environment.

Package: Plastic bags – paper cartons – pallet

MOQ: 10,000.00 pieces

Delivery Time: Fast delivery, within 15-30 days which depends on the order quantity and production arrangement.

Payment: T/T Telegraphic Transfer or L/C Letter of Credit

Product Features

The aluminum layer is sealed on the lip of container.

The secondary layer (cardboard of form) is left in the cap.

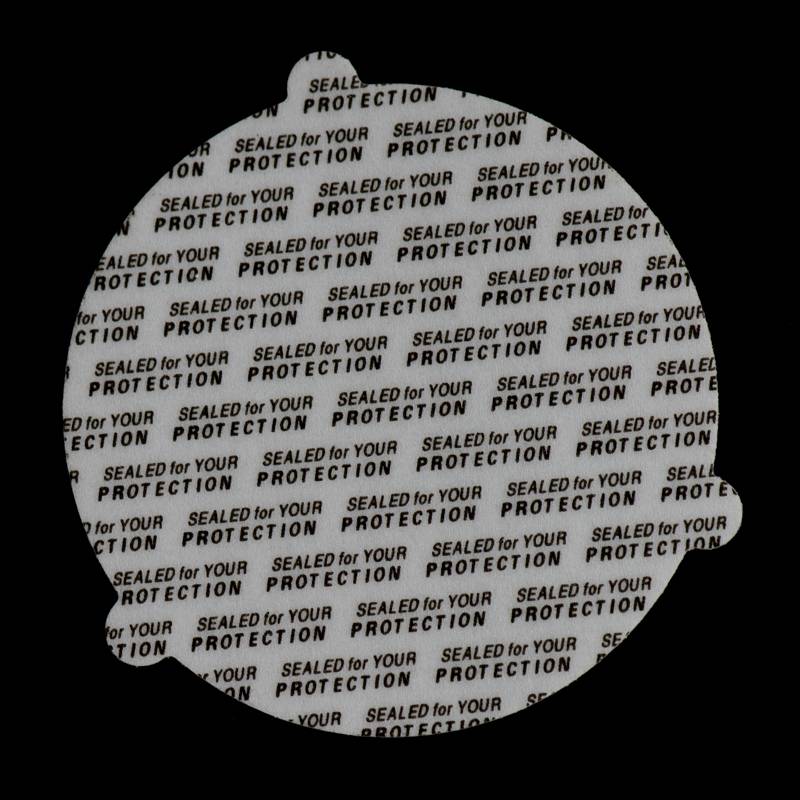

Print patterns or trademarks on the inner paper layer

Suitable for the screw capping PET, PP, PS, PE, high barrier plastic bottles

Good heat sealing.

A wide heat sealing temperature range.

High quality, non-leakage, anti-puncture, high clean, easy & strong sealing.

Barrier of air and moisture.

Long guarantee time.

Application

1- Motor, Engine, and Lubricant Oil products

2- Edible Oil products

3- Medicine products (Pharmaceutical factories for Tablet, Gel, Cream, Powders, Liquids, etc.)

4- Food Products.

5- Beverages, Fruit Juice, Butter, Honey, Mineral Water

6- Pesticides, Fertilizers, and Chemicals

7- Cosmetics

Recommendation

• Agrochemicals

• Pharmaceuticals

• Nutraceutical Products

• Foods & Beverages

• Lubricants

• Cosmetics, etc.

Factors Affecting Sealing

Contact width of sealing surface: the larger the contact width between sealing surface and gasket or packing, the longer the path of fluid leakage and the greater the flow resistance loss, which is beneficial to sealing. However, under the same compression force, the larger the contact width, the smaller the specific pressure. Therefore, the appropriate contact width should be found according to the material of the seal.

Fluid temperature: the temperature affects the viscosity of the liquid, thus affecting the sealing performance. With the increase of temperature, the viscosity of liquid decreases and the viscosity of gas increases. On the other hand, the change of temperature often leads to the deformation of the sealing components and easy to cause leakage.

Product detail pictures:

Related Product Guide:

carry on to boost, to guarantee products excellent in line with market and consumer standard specifications. Our enterprise has a quality assurance system are actually established for Manufacturing Companies for Vented Seal Liners - Two-piece Heat Induction Seal Liner with Paper Layer – Ziling Packaging , The product will supply to all over the world, such as: Berlin, Liverpool, South Africa, We always insist on the management tenet of "Quality is First, Technology is Basis, Honesty and Innovation".We are able to develop new products continuously to a higher level to satisfy different needs of customers.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.