Products

OEM Customized Pressure Sensitive Liners - Two-Piece Heat Induction Seal Liner With “A Structure” – Ziling Packaging

OEM Customized Pressure Sensitive Liners - Two-Piece Heat Induction Seal Liner With “A Structure” – Ziling Packaging Detail:

Two-piece Heat Induction Seal Liner with A Structure

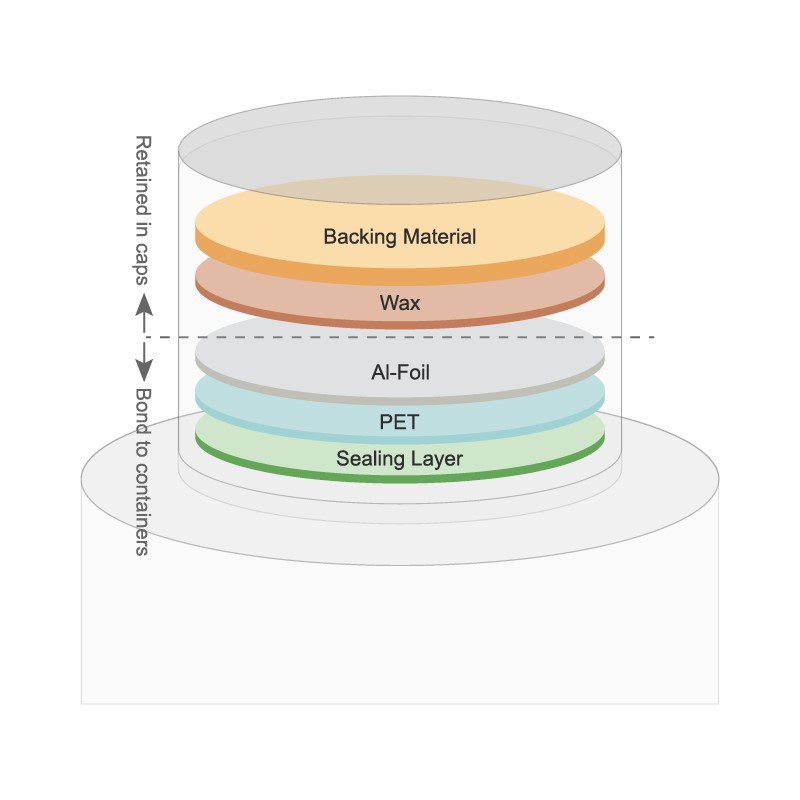

This liner is made up of aluminum foil layer and backup layer. It needs the induction seal machine. After induction machine provides a heat-seal laminate hermetically sealed to the lip of a container, the aluminum layer is sealed on the lip of the container and the secondary layer (cardboard of form) is left in the cap. The secondary liner as the reseal liner is left in the cap after heating process.

Specification

Raw material: Backing Material + Wax + Aluminum Foil + Plastic Film + Sealing Film

Backing Material: Pulp board or Expanded Polyethylene (EPE)

Sealing Layer: PS, PP, PET, EVOH or PE

Standard Thickness: 0.2-1.7mm

Standard Diameter: 9-182mm

We accept customized logo, size, packaging and graphic.

Our products can be die-cut into different shapes and sizes upon request.

Heat sealing temperature: 180℃-250℃, depend on the material of the cup and the environment.

Package: Plastic bags – paper cartons – pallet

MOQ: 10,000.00 pieces

Delivery Time: Fast delivery, within 15-30 days which depends on the order quantity and production arrangement.

Payment: T/T Telegraphic Transfer or L/C Letter of Credit

Product Features

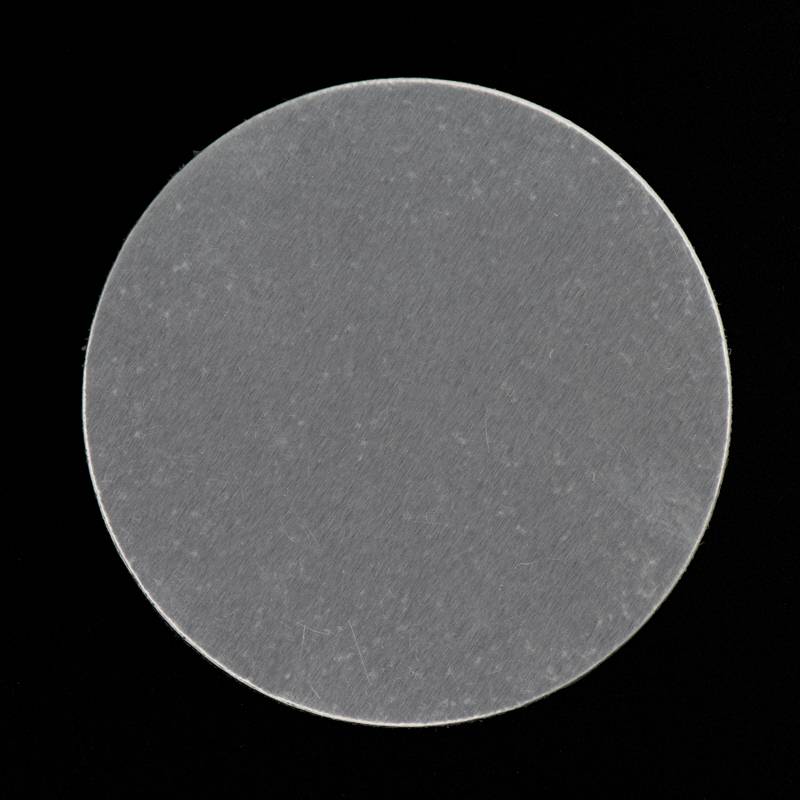

Aluminum foil is the first layer of whole aluminum foil layer.

The aluminum layer is sealed on the lip of container.

The secondary layer (cardboard of form) is left in the cap.

Suitable for the screw capping PET, PP, PS, PE, high barrier plastic bottles

Good heat sealing.

A wide heat sealing temperature range.

High quality, non-leakage, anti-puncture, high clean, easy & strong sealing.

Barrier of air and moisture.

Long guarantee time.

Benefits

1. Very easy to open

2. Seals in freshness

3. Prevent costly leaks

4. Reduce the risk of tampering, pilferage, and contamination

5. Extend shelf life

6. Create hermetic seals

7. Environment friendly

Factors affecting sealing

Contact width of sealing surface: the larger the contact width between sealing surface and gasket or packing, the longer the path of fluid leakage and the greater the flow resistance loss, which is beneficial to sealing. However, under the same compression force, the larger the contact width, the smaller the specific pressure. Therefore, the appropriate contact width should be found according to the material of the seal.

Fluid properties: the viscosity of the liquid has a great impact on the sealing performance of the packing and gasket. The fluid with high viscosity is easy to seal due to its poor fluidity. The viscosity of liquid is much higher than that of gas, so liquid is easier to seal than gas. Saturated steam is easier to seal than superheated steam because it will condense and precipitate droplets and block the leakage channel between sealing surfaces. The larger the molecular volume of the fluid, the easier it is to be blocked by the narrow sealing gap, so it is easy to seal. The wettability of the liquid on the sealing material also has some influence on the sealing. The liquid which is easy to soak is easy to leak due to the capillary action of the micro pores in the gasket and packing.

Product detail pictures:

Related Product Guide:

We are proud of the high customer satisfaction and wide acceptance due to our persistent pursuit of high quality both on product and service for OEM Customized Pressure Sensitive Liners - Two-Piece Heat Induction Seal Liner With “A Structure” – Ziling Packaging , The product will supply to all over the world, such as: azerbaijan, Tanzania, Orlando, In order to meet our market demands, we have paied more attention to the quality of our products and services. Now we can meet customers' special requirements for special designs. We persistently develop our enterprise spirit "quality lives the enterprise, credit assures cooperation and keep the motto in our minds: customers first.

A good manufacturers, we have cooperated twice, good quality and good service attitude.