Products

OEM/ODM Factory Induction sealing wad for glass jar - Pressure Sensitive Seal Liner – Ziling Packaging

OEM/ODM Factory Induction sealing wad for glass jar - Pressure Sensitive Seal Liner – Ziling Packaging Detail:

Pressure-Sensitive Seal Liner

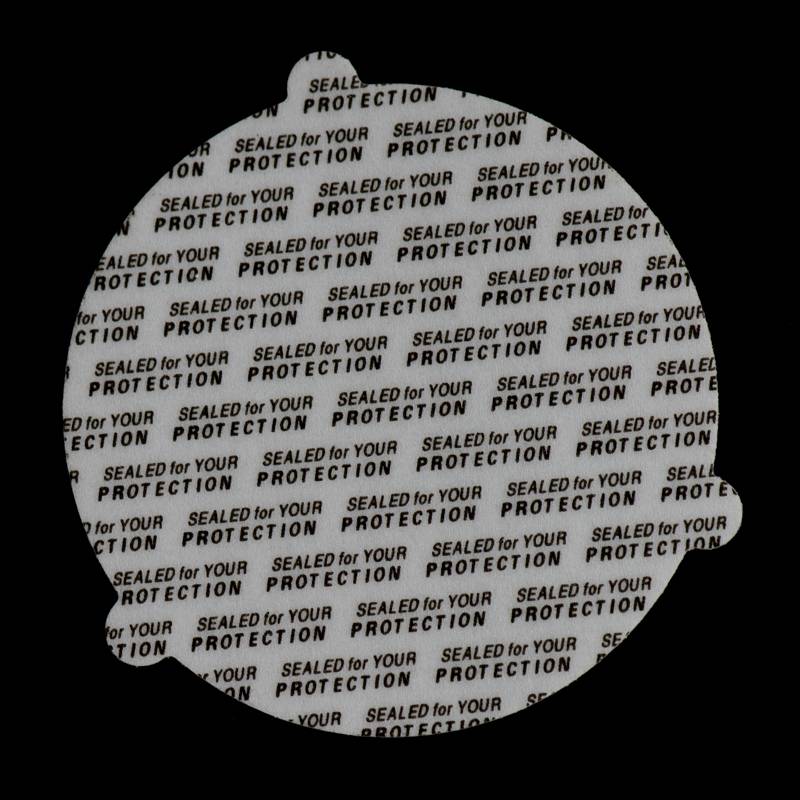

The liner is composed of foam material coated with high quality pressure sensitive. This liner is also called one-piece liner. It provides tight seal with the adhesive to the container by the pressure only. Without any seal and heating devices. like the hot melt adhesive induction seal liner, is available to all kinds of containers: plastic, glass and metal containers. But it’s not designed for barrier properties, the effects is less than the former, so is recommended to use for solid an powdered goods, such as food, cosmetic and health care products.

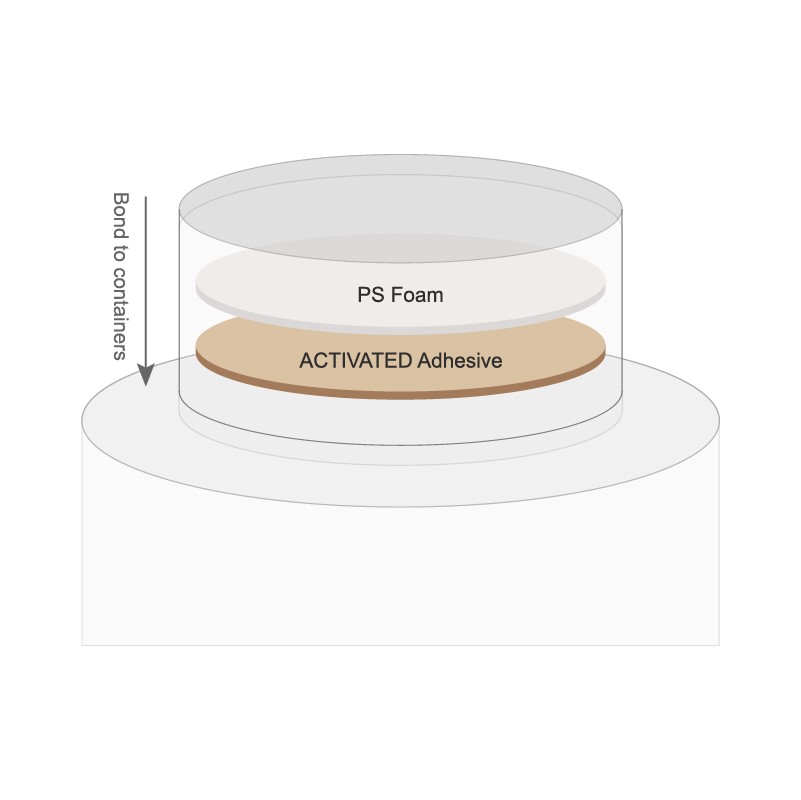

Pressure Sensitive Seal is a one piece, reusable product. It consists of a foamed polystyrene coated on one side with pressure sensitive adhesive. The liner can seal the container after the bottle cap is pressed tightly.

Structurally similar to a foam liner, pressure sensitive liners have adhesive on one side, designed to stick on to the rim of a container. When a container is closed and pressure is applied to the cap (and in turn, the liner), the adhesive becomes activated, which creates a seal.

Pressure sensitive liners provide an extra level of protection in that it actually creates a seal that sticks to the rim of the bottle. Pressure seals are not considered a form of tamper evident seal. They do not work well with liquids, especially oils. They can, at times, work with thick liquids such as creams and sauces.

Specification

Raw material: PS Form + Pressure-Sensitive Adhesive

Sealing Layer: PS

Standard Thickness: 0.5-2.5mm

Standard Diameter: 9-182mm

We accept customized size & packaging

Our products can be die-cut into different shapes and sizes upon request.

Package: Plastic bags – paper cartons – pallet

MOQ: 10,000.00 pieces

Delivery Time: Fast delivery, within 15-30 days which depends on the order quantity and production arrangement.

Payment: T/T Telegraphic Transfer or L/C Letter of Credit

Product Features

Sealing without any machines.

High quality, non-leakage, anti-puncture, high clean, easy & strong sealing.

Barrier of air and moisture.

Long guarantee time.

Purpose

1.Dry products

2.Dry food / powders

3.Thick liquids

Factors Affecting Sealing

Specific pressure of sealing surface: the normal force on the unit contact surface between sealing surfaces is called sealing specific pressure. The specific pressure of sealing surface is an important factor affecting the sealing performance of gasket or packing. Usually, a certain specific pressure is produced on the sealing surface by applying the pre tightening force, which makes the seal deform, so as to reduce or eliminate the gap between the sealing contact surfaces and prevent the fluid from passing through, so as to achieve the purpose of sealing. It should be pointed out that the effect of fluid pressure will change the specific pressure of sealing surface. The increase of the specific pressure of the sealing surface is beneficial to the sealing, but it is limited by the extrusion strength of the sealing material; for the dynamic seal, the increase of the specific pressure of the sealing surface will also cause the corresponding increase of the friction resistance.

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our organization for your long-term to establish alongside one another with shoppers for mutual reciprocity and mutual benefit for OEM/ODM Factory Induction sealing wad for glass jar - Pressure Sensitive Seal Liner – Ziling Packaging , The product will supply to all over the world, such as: Seattle, Vietnam, Ukraine, The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.